MARSHALL Product Quality

The company made the product quality and vehicle safety its first priority. When manufacturing spare parts, the MARSHALL Autoparts B.V experts are guided by standards of the global leaders in the commercial vehicle production. Special attention is paid to material and product quality control at all stages of production. Almost all MARSHALL spare parts have a 2-year warranty.

Equipment

Manufacturing process at MARSHALL is characterized by a high degree of automation. Spare parts are manufactured using robot-operated machines made by world leading manufacturers of industrial equipment and assembly lines. This equipment takes advantage of modern part-processing technologies, which ensure long service life even under extreme climatic conditions and during high work loads.

Raw materials

Raw materials used for manufacturing MARSHALL spare parts undergo strict incoming control, certification checks and evaluation for compliance with quality standards of original manufacturers. Raw materials ready for machining, are analyzed in various ways, depending on what it is going to be used for. Only high-quality materials are used in production of MARSHALL spare parts.

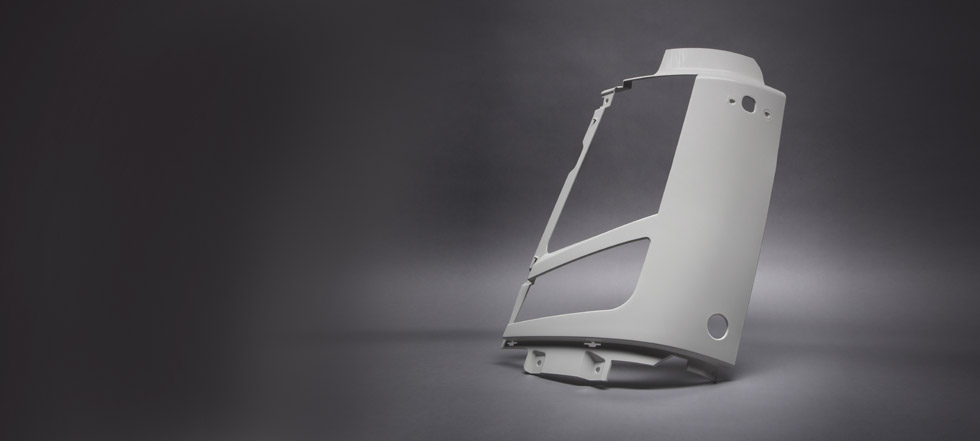

Finished Products

Finished products undergo tests by various types of equipment, depending on the type of tested parts:

- geometrical dimensions inspection;

- balancing features inspection;

- environmental stability test;

- out-of-roundness gauging;

- inspection for hidden internal flaws;

- performance tests and life-cycle tests.

Shipping and Logistics

Storage and transportation of the MARSHALL spare parts are implemented in compliance with high product quality principles and the top service standards. Thanks to the unique packaging and work done by experts, the MARSHALL spare parts retain their quality, since they are not exposed to environmental impacts while being delivered and stored at the company warehouses.