- Springs

- Spring U-Bolts

- Drum Brake Shoes

- Brake Drums and Brake Discs

- Landing Gears

- Fifth Wheel Couplings

- Shock absorbers

- Hubs

- Rods and Rod Ends

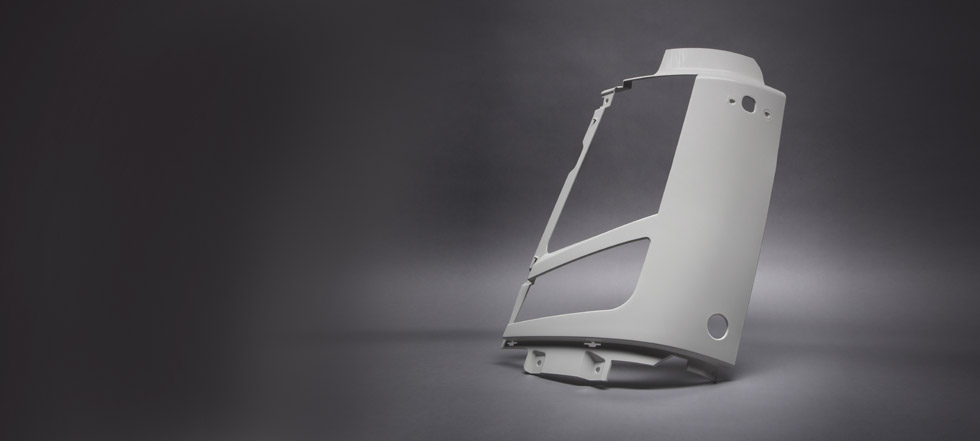

- Body parts

- Slack adjusters

- Mirrors

- Brake Chambers and Spring Brake Chambers

- Caliper repair kits

- Bolts and Nuts

- Brake Camshafts and Brake Camshaft Repair Kits

- Cab tilt pumps and cylinders

- Air valves

- Water pumps

- Trailer cables and connectors

- Rubber Metal Parts

- Air brake compressors and repair kits

- Drive belt tensioners and rollers

- Fan clutches

- Radiators

- Drive belts

Trailer cables and connectors

MARSHALL offers a wide range of trailer cables and connectors for European commercial vehicles.

The assortment includes all in-demand models of spiral coils, sockets, plugs, and adaptors which are required for different connection standards on truck and semi-trailer.

The manufactory of MARSHALL trailer cables and connectors is equipped with modern facilities and laboratory and is also certified to IATF 16949:2016.

The assortment includes all in-demand models of spiral coils, sockets, plugs, and adaptors which are required for different connection standards on truck and semi-trailer.

The manufactory of MARSHALL trailer cables and connectors is equipped with modern facilities and laboratory and is also certified to IATF 16949:2016.

.jpg)

Advantages of MARSHALL trailer cables and connectors:

High-quality materials

A copper wire serves as a conductor for MARSHALL trailer cables, which ensures reliable contact and flawless power supply to the equipment.

Injection moulding of plug and socket bodies is made of engineering plastic PA6 — polymer material of high robustness, which ensures the durability of MARSHALL connectors.

Socket springs — components, most susceptible to atmospheric conditions — are made of stainless steel.

Injection moulding of plug and socket bodies is made of engineering plastic PA6 — polymer material of high robustness, which ensures the durability of MARSHALL connectors.

Socket springs — components, most susceptible to atmospheric conditions — are made of stainless steel.

Conductor cross-section corresponds to the global standards

Сross-section of N-type and S-type cables: 6×1mm²+1×1,5mm².

Cross-section of EBS cables: 2×4mm²+5×1,5mm².

Cross-section of 15-pin cables: 12×1,5mm²+3×2,5mm².

Cross-section of EBS cables: 2×4mm²+5×1,5mm².

Cross-section of 15-pin cables: 12×1,5mm²+3×2,5mm².

Product testing

100% of assembled cables are tested on a testing bench.

Various design options

Part’s body material: metal or plastic.

Termination method: screw, spade or crimp.

Termination method: screw, spade or crimp.

MARSHALL trailer cables and connectors have a 2-year warranty.