- Springs

- Spring U-Bolts

- Drum Brake Shoes

- Brake Drums and Brake Discs

- Landing Gears

- Fifth Wheel Couplings

- Shock absorbers

- Hubs

- Rods and Rod Ends

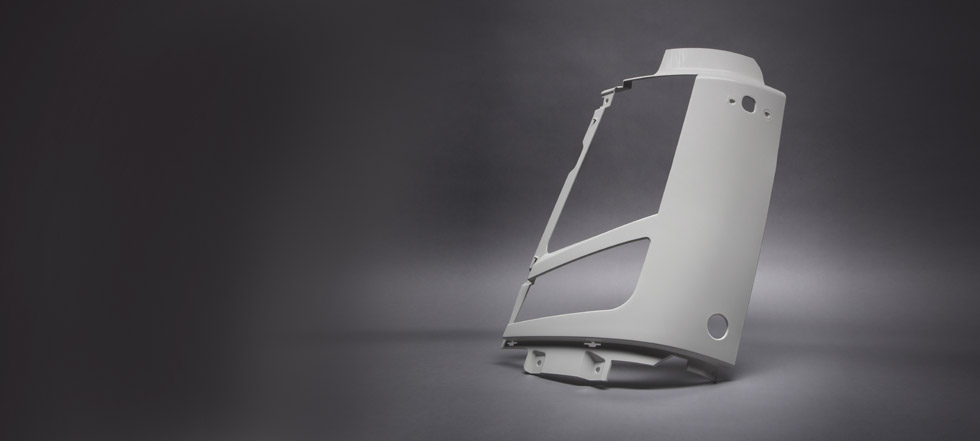

- Body parts

- Slack adjusters

- Mirrors

- Brake Chambers and Spring Brake Chambers

- Caliper repair kits

- Bolts and Nuts

- Brake Camshafts and Brake Camshaft Repair Kits

- Cab tilt pumps and cylinders

- Air valves

- Water pumps

- Trailer cables and connectors

- Rubber Metal Parts

- Air brake compressors and repair kits

- Drive belt tensioners and rollers

- Fan clutches

- Radiators

- Drive belts

Slack adjusters

MARSHALL slack adjusters are manufactured by companies specializing in brake parts manufacturing for over 30 years.

Production area is equipped with automated casting lines, equipment for cold rolling and induction hardening; machining is performed using modern German and Japanese – CNC machines.

Strict quality control of MARSHALL slack adjusters is also achieved through the ERP-system implemented into the production, which allows monitoring the status of products at any stage of the production cycle and promptly correcting any defects arising.

The range of MARSHALL slack adjusters is comprised of more than 600 items, including automatic and manual slack adjusters for all popular models of trucks.

MARSHALL slack adjusters have the following advantages:

Self-adjusting mechanism

Installation of slack adjuster is very simple and easy - self-adjusting mechanism S-ABA allows not to waste time on setting the required clearance, thus you can avoid improper installation.

Due to continuous adjustment of the correct angle, automatic MARSHALL slack adjusters improve by 50% the effectiveness and durability of braking system and its individual components (brake pads, drum, drum shoes, rollers and brake chamber).

Reinforced construction of adjuster cover plate

Test results indicate that failures related to the cover plate constitute about 36% of all cases of failure of slack adjusters. MARSHALL slack adjusters are manufactured with reinforced cover plate, which has an increased stiffness, whereby it is less susceptible to deformations and provides a snug fit to the housing. As a result, slack adjusters mechanism is protected from moisture, dirt and damages.

Control valve for excess oil discharge

On an average 80-85 grams of grease is used in slack adjusters. With its abundance within the mechanism, increased pressure created there pushes the excess oil on the surface of adjuster. This leads to the fact that the sealing elements (such as O-rings and gaskets) may gradually melt and eventually cause damage of the product.

Control valve, provided in MARSHALL slack adjusters mechanism, helps to remove oil excess. This prevents premature failure of individual components of the product and improves products durability.

Warranty period for MARSHALL slack adjusters is 2 years.