- Springs

- Spring U-Bolts

- Drum Brake Shoes

- Brake Drums and Brake Discs

- Landing Gears

- Fifth Wheel Couplings

- Shock absorbers

- Hubs

- Rods and Rod Ends

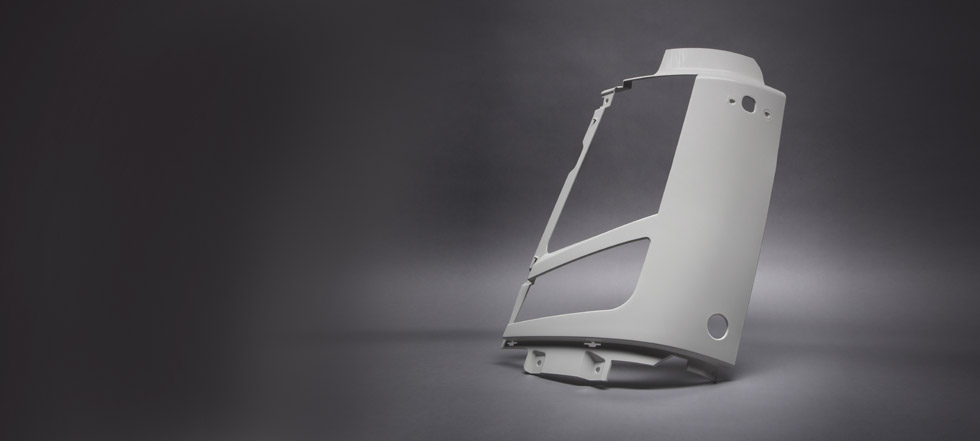

- Body parts

- Slack adjusters

- Mirrors

- Brake Chambers and Spring Brake Chambers

- Caliper repair kits

- Bolts and Nuts

- Brake Camshafts and Brake Camshaft Repair Kits

- Cab tilt pumps and cylinders

- Air valves

- Water pumps

- Trailer cables and connectors

- Rubber Metal Parts

- Air brake compressors and repair kits

- Drive belt tensioners and rollers

- Fan clutches

- Radiators

- Drive belts

Hubs

Manufacturing of the MARSHALL hubs is a highly automated process. The factory has its own foundry furnished with equipment by DISA company (Denmark). Machining is done using You-Ji automated lines (Taiwan).

The MARSHALL hubs have a number of benefits:

High Wear Resistance

The MARSHALL hubs are made of high-strength ductile iron supplied by Rio Tinto Group, the leading company in the Canadian foundry industry, and conforms to the international standard GGG50. Conformance to the standard is guaranteed, due to all billets pass the optic-emission analysis before machining for precisely verification of metal chemical composition. Also, billets are tested for resistance to dents on surfaces and for tensile strength. As a result, the MARSHALL hubs are manufactured using only high-strength ductile iron, brittle fracture hazard of which is minimized even in laden condition and during operation on uneven road pavement.

Suitability for Extreme Driving and Weather Conditions

Temperature differences and road treatment with deicing agents may cause premature failure of wheel hubs, if the latter are made of the low-grade material. Reinforced by alloy elements, the GGG50 cast iron is highly resistant to thermal impacts, acids and alkalies, and has good antifriction properties, which makes parts made of this cast iron well suited for operation in extreme conditions.

All MARSHALL hubs, which are assembled with bearings, are tested on the test bed that imitates the wheel rotation on the real axis. As a result of this test, the occured gap is measured and conclusion is made whether that wheel hub is suitable for operation.

Absence of Vibrations in the Brake Assembly

Improper alignment of hub on axis (due to drum holes being located at random distances from the center, 'out-of-roundness' of hub or bearing holes) results in occurrence of vibration in the brake assembly and may cause its inoperability. Each MARSHALL hub is inspected on micrometric equipment for compliance with required dimensions. As a result, parts with improper geometrical dimensions are rejected, thus, probability of vibration occurrence is practically eliminated.

The MARSHALL hubs have a 2-year warranty.